By

Komatsu Ltd

Komatsu Australia Pty Ltd

Designed in

Japan

Description

The Komatsu hybrid excavator utilises regeneration of electrical power, engine assist for power on demand, ultra low engine idle and a smaller engine to achieve reduced fuel consumption and lower CO2 emissions.

It is the world's first commercially produced hybrid excavator and is available in the 20 tonne class, the most popular size machine in the global market.

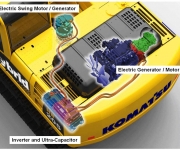

The hybrid system includes an electric motor generator, swing motor generator and ultra capacitor with inverter.

It is separate from the conventional excavator electrical system, is double insulated and contains numerous safety devices to protect the user and the system from damage.

Key Features

and/or Benefits

The swing motor generator uses electricity from the capacitor or generator motor to drive the upper structure swing function. During swing braking, the swing motor generator converts kinetic energy into electrical power and sends it to the capacitor via the inverter.

The generator motor generates electric power with engine torque to drive the swing motor or charge the capacitor when necessary.

The inverter converts electricity from the swing motor generator or generator motor from AC to DC for storage in the capacitor and from DC to AC to supply the swing motor or generator motor for engine assist as required.

The generator motor generates electric power with engine torque to drive the swing motor or charge the capacitor when necessary.

The inverter converts electricity from the swing motor generator or generator motor from AC to DC for storage in the capacitor and from DC to AC to supply the swing motor or generator motor for engine assist as required.

The engine assist function gives the hybrid excavator the unique ability to provide power on demand utilising only the engine RPM required for the operation.

During work, conventional excavators control hydraulic pump delivery while keeping the engine running at a specified speed. Hybrid excavators employ engine pump matching technology allowing the engine to run at the lowest possible speed while maintaining the necessary oil flow. Engine speed is matched with pump delivery at a point where the fuel efficiency is high, further reducing fuel consumption. Low speed matching requires the engine to change its speed frequently, engine assist enables this.

During work, conventional excavators control hydraulic pump delivery while keeping the engine running at a specified speed. Hybrid excavators employ engine pump matching technology allowing the engine to run at the lowest possible speed while maintaining the necessary oil flow. Engine speed is matched with pump delivery at a point where the fuel efficiency is high, further reducing fuel consumption. Low speed matching requires the engine to change its speed frequently, engine assist enables this.

The engine is set at an ultra low idle speed of 700 RPM compared to 1050 RPM in the equivalent Komatsu conventional excavator further contributing to fuel savings. Energy stored in the capacitor is used to drive the generator motor that assists engine acceleration allowing the engine to rapidly reach the RPM necessary to provide equivalent performance to the conventional Komatsu excavator.

The engine assist function enabled by the motor generator means the engine can be downsized from a six cylinder engine (as is used in the equivalent Komatsu conventional excavator) to a four cylinder engine. The use of a smaller engine further contributes to reduced fuel consumption and lower emissions.