By

kwik-ZIP Pty Ltd

Applidyne Australia Pty Ltd

Designed in

Australia

Description

A greener, more cost effective and more reliable centralizer with greater flexibility for keeping pipes centred in wells and drains.

When the oil well that the Deepwater Horizon rig was drilling in the Gulf of Mexico blew out in 2010 causing one of the worst oil spills in US history, the role of centralizers became a focus for investigators. In many wells, the area between the pipe and well is filled with concrete, in a process termed "grouting" to provide a secure installation. Failure to do this properly in BP's Gulf of Mexico incident led to the well blowing out.

Key Features

and/or Benefits

Centralizers are used in many applications other than oil wells. Underground drainage pipes and water wells are two examples. Traditionally heavy, expensive steel centralizers have been used. Kwik-ZIP identified the need for a cheaper centralizer in these applications that was also quicker and easier to install, using the latest in high strain capacity engineering thermoplastics.

The HD Series centralizers comply with AS4020:1999, ensuring that water from wells fitted with the centralizers is safe to drink. The absence of metal parts ensures that there is no issue with corrosion.

Conventional steel centralizers corrode over time potentially leading to leaks in the well's grout seal. This can allow polluted fluid to enter the aquifer. Non-metallic centralizers do not pose this risk.

Conventional steel centralizers corrode over time potentially leading to leaks in the well's grout seal. This can allow polluted fluid to enter the aquifer. Non-metallic centralizers do not pose this risk.

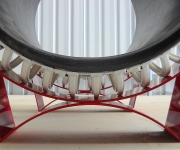

Centralizers are attached together until the combined length is sufficient to span the circumference of the pipe. They are then tightened around the pipe so they will not slide along the pipe when the pipe is inserted into the well or outer pipe. Integrated rubber pads prevent slippage. Each centralizer band incorporates a ratchet type mechanism, similar to a zip-tie, that engages the adjacent centralizer. These are used to achieve a snug fit on the pipe. A patented worm drive fastener on each band then allows the operator to tension the straps using a screwdriver to rotate the worm.

The ratchet band arrangement allows much faster installation than conventional centralizers. A centralizer band can be assembled in seconds. The low coefficient of friction of the bows and the curved profile then ensures easy installation of the centralizer band into the well or outer pipe, further reducing installation time.

For grouted applications, it is imperative that the grout can flow freely and that there are no voids. The axial profile of the HD series centralizers has been designed to allow free flow and avoid pockets where grout cannot penetrate readily. This is very important in ensuring a safe installation.

For grouted applications, it is imperative that the grout can flow freely and that there are no voids. The axial profile of the HD series centralizers has been designed to allow free flow and avoid pockets where grout cannot penetrate readily. This is very important in ensuring a safe installation.

Each centralizer in the HD Series range has exceptional flexibility to cope with a range of diametral clearances. This is achieved by using an exceptional thermoplastic which is capable of strains in excess of 300% without failure. Available in 4 different sizes, with bow heights ranging from 30mm to 100mm, the range covers every combination of pipe diameters likely to be found in service. The exceptional flexibility also allows very high temporary deflections, such as when clearing an obstruction such as a boulder or caved-in formation in a ground bore.